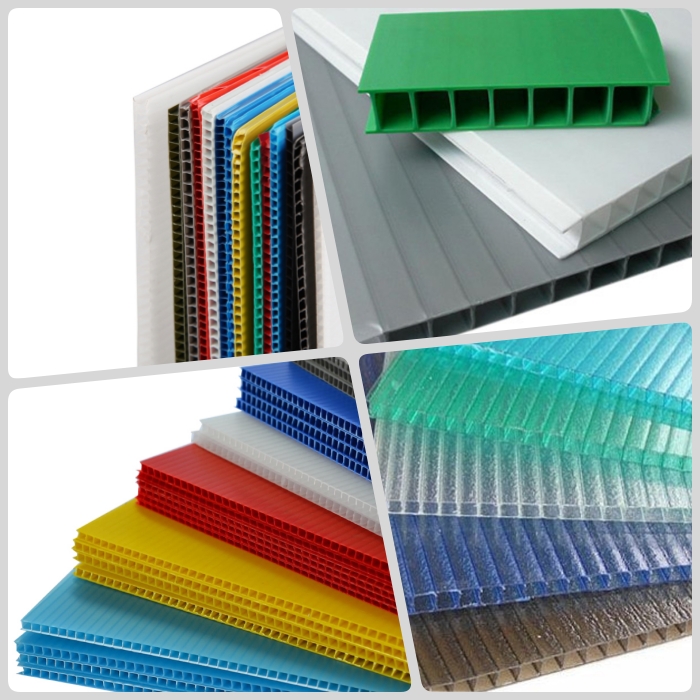

Corflute Sheet

Product Description

Compared with injection molded products, the corflute sheet has the advantages of anti-vibration, flexible design structure, without opening the injection mold. At the same time, the plate can be flexible through the control of raw materials to join the anti-static, conductive masterbatch, etc., to produce a conductive, anti-static function of the plastic corflute sheet sheet, anti-static sheet surface resistivity can be controlled between 106 ~ 1011. Conductive sheet surface resistivity can be controlled between 103 ~ 105.

PP corflute sheet is a kind of green environmental protection material, application is very wide, gradually replace part of the corrugated paper packaging materials, and now some enterprises are also being developed for use as building decoration materials! PP corflute sheet because of its wide range of applications, easy to use, also known as the Vantone board, which is widely used in advertising background, stationery materials, industrial packaging, product shockproof, etc., we are the most common have a turnover box, removable combination of boxes, finished product packaging box As well as the box in the partition and so on. corflute sheet is generally made of environmentally friendly and non-polluting recyclable thermoplastic polypropylene (PP), polyethylene (HDPE) resin and a variety of auxiliary materials, and there is a polycarbonate (PC) corflute sheet, also known as sunshine board, glass Kaplan board, PC corflute sheet, is a high-performance engineering plastics PC resin processed from high transparency, lightweight, impact resistance, acoustic, thermal insulation, flame retardant, anti-aging characteristics, is a high-tech, comprehensive performance of the PC resin processing and made of Characterized by high transparency, light weight, impact resistance, sound insulation, heat insulation, flame retardant, anti-aging, etc., it is a high-tech, excellent comprehensive performance, energy-saving and environmentally friendly plastic panels, and is currently a commonly used plastic building materials.

Corflute Sheet is a twin wall profile extrusion, connected by a series of vertical ribs, also called corrugated plastic sheet, correx sheet, PP coroplast sheet. The corflute sheet can be widely used in packaging, advertising, construction, agriculture, hardware, layer pad industry and others.

Specification

Product name | Corflute Sheet | |||||||

Size | customer size | |||||||

Thickness | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 10mm | 12mm |

GSM(g/m²) | 280-400 | 350-500 | 550-1000 | 800-1500 | 900-2000 | 1200-2500 | 2500-3000 | 3000-3500 |

Color | white, blue, green, black, red, prink, yellow, grey and so on | |||||||

Properties | 1. Unaffected by water. | |||||||

2. Stronger and more durable than corrugated fiberboard. | ||||||||

3. Extremely lightweight. | ||||||||

4. Won't rust, rot, mildew or corrode like metal or wood. | ||||||||

5. Can be printed on easily and clearly. | ||||||||

6. Tear, puncture and impact-resistant. | ||||||||

7. Can be scored, creased, stapled, nailed, stitched, folded & drilled | ||||||||

8. Can be made for die-cut. | ||||||||

9. Can be sonic or heat welded. | ||||||||

10. Resists a wide range of chemicals, grease and dirt. | ||||||||

11. Can be produced with a non-skid coating on one side. | ||||||||

Options | 1. Flame Retardant | |||||||

2.Corona treatment | ||||||||

3.Anti-Static | ||||||||

4.Conductive | ||||||||

5.Ultra-violet inhibiting | ||||||||

Application

1.Graphics: Advertising Board, Yard Sign, Letters, Warning Board,

2.Packaging: Converted into boxes, bins, totes dividers. It is ideal for indoor and outdoor applications.

3.Agriculture: Tree guard to protect sapling

4.Industrial: Padding, setting plate (Baby carriage, delivery box)

5.Construction: Protection for floor, wall

6.Other: Floral display stand

FAQ:

Q: What do you produce?

A: Mantis specializes in the production, research, and development of corrugated plastic sheets, PP layer pads and reusable plastic packaging boxes for various industries.

Q: How do you guarantee the production quality?

A: We'll present a pre-production sample to the client for approval before the mass production, meanwhile, we also do the quality inspection during the production and before the shipment.

Q: What makes you different from the competitors?

A: *Effective services

*Good quality control

*Smooth communication

*Highly competitive prices

Q: How fast do you ship the orders?

A: It usually takes us 5 -15 days to implement the order's production and arrange the shipment booking with the forwarding agents.