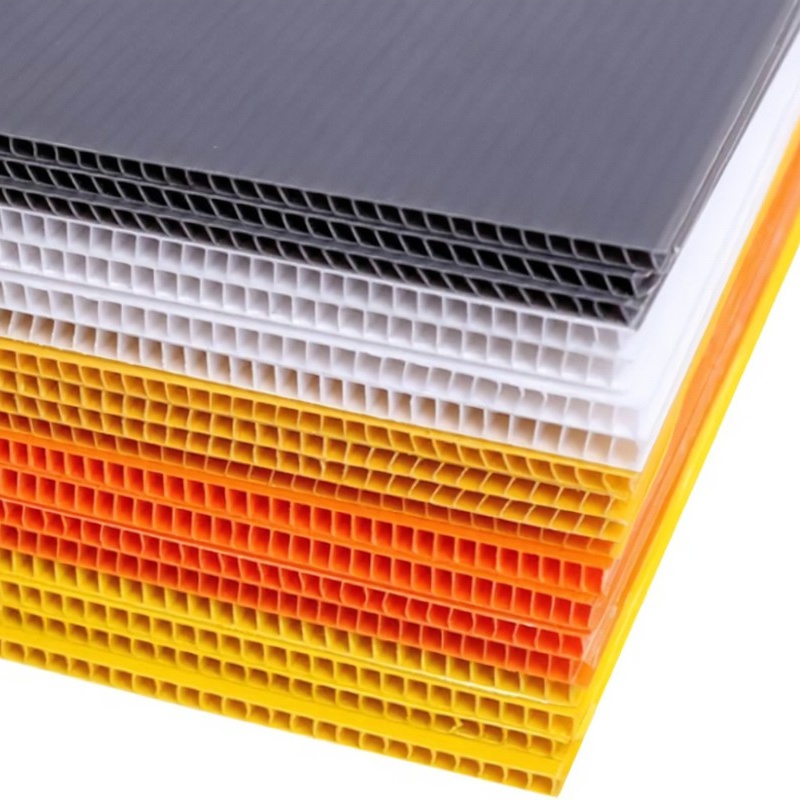

In an age where material innovation and environmental responsibility are paramount, corrugated plastic sheets have emerged as a remarkably versatile and sustainable solution for countless applications. Known by various names such as Coroplast, fluted polypropylene, or Corflute, this material features a unique cellular structure that provides exceptional strength and rigidity while remaining impressively lightweight. The composition typically involves two flat polypropylene sheets fused to a central core of fluted ribs, creating a panel that is not only durable and waterproof but also fully recyclable and often made from recycled content. This combination of practicality and ecological sensibility makes corrugated plastic sheets an increasingly preferred choice across diverse industries, from construction and signage to packaging and creative projects.

One of the most compelling aspects of corrugated plastic sheets is their outstanding durability paired with surprising lightness. Unlike heavier materials such as plywood, metal, or solid plastic, these sheets offer substantial impact resistance and weatherproof qualities without the burden of excessive weight. This makes them exceptionally easy to transport, handle, and install in various settings. They are completely waterproof and will not rot, corrode, or degrade when exposed to moisture, making them ideal for both indoor and outdoor applications. Additionally, high-quality sheets are treated to resist ultraviolet light, preventing fading and brittleness when used in sunny conditions. This resilience ensures that products and structures made from corrugated plastic maintain their integrity and appearance over extended periods, providing long-term value and reliability for users.

The environmental profile of modern corrugated plastic sheets represents a significant advancement in material science. Many manufacturers now produce these sheets using recycled polypropylene derived from post-consumer or post-industrial sources. This process diverts plastic waste from landfills and reduces the demand for virgin petroleum-based materials, conserving natural resources and energy. Furthermore, at the end of its useful life, the material itself is 100% recyclable, allowing it to re-enter the production cycle and continue its service in new forms. This commitment to a circular economy stands in stark contrast to single-use plastics or composite materials that cannot be easily separated and recycled. For businesses and individuals seeking to reduce their environmental footprint without compromising on performance, corrugated plastic sheets offer a responsible choice that aligns with contemporary sustainability goals.

When it comes to practical applications, few materials can match the sheer versatility of corrugated plastic sheets. In the signage and display industry, they are the go-to material for both temporary and semi-permanent signs, election posters, real estate signage, and exhibition displays due to their printable surface and weather resistance. The packaging sector utilizes them to create reusable shipping containers, protective layer pads between heavy goods, and durable boxes that outlast traditional cardboard many times over. Construction and event professionals value them for temporary floor and wall protection, lightweight barriers, and even as a material for model-making and prototyping. Creative minds have discovered their potential for crafting, school projects, and artistic installations, where they can be easily cut, shaped, and assembled with basic tools. This wide-ranging utility stems from the material's unique balance of properties, which can be customized through variations in thickness, color, and surface treatment to meet specific needs.

Another significant advantage of corrugated plastic sheets is their exceptional ease of fabrication and customization. Unlike many rigid materials, they can be cut cleanly with standard utility knives, saws, or die-cutting machines, requiring no specialized equipment for basic shaping. They can be folded along the flutes to create boxes or stands, and they accept a wide variety of fastening methods, including staples, rivets, and adhesives. For professional applications, they are perfectly suited to advanced digital printing, allowing for full-color, high-resolution graphics to be applied directly to the surface. Waterjet cutting technology can be employed to create intricate, precise shapes and patterns from these sheets, enabling complex designs for decorative bricks, custom displays, or architectural features. This adaptability empowers users at all levels—from large-scale manufacturers to DIY enthusiasts—to work with the material effectively and bring their visions to life with minimal complication.

From an economic perspective, corrugated plastic sheets deliver considerable value. Their initial cost is typically competitive with, and often lower than, alternative materials offering similar protective or structural functions. However, the true savings emerge through their longevity and reusability. A sign made from this material can withstand multiple seasons of weather where paper or cardboard would fail instantly. A packaging box or protective pad can make dozens of trips in a logistics chain, whereas single-use alternatives would need constant replacement. This durability translates directly into reduced material costs over time, less waste generation, and lower labor expenses associated with frequent replacement. For businesses, this creates a compelling return on investment, combining upfront affordability with long-term performance that minimizes total cost of ownership while supporting operational efficiency and sustainability objectives.

In conclusion, corrugated plastic sheets stand as a testament to how intelligent design can create a material that excels in multiple dimensions. They provide a rare convergence of strength, lightness, and weather resistance that serves practical needs across numerous fields. Their evolving production, increasingly rooted in recycled content and recyclability, addresses the urgent global priority of sustainable material use. The ease with which they can be customized and fabricated unlocks creativity and efficiency for professionals and hobbyists alike. Whether serving as a protective layer on a construction site, a vibrant sign guiding customers, a sturdy box safeguarding products in transit, or a canvas for artistic expression, corrugated plastic sheets offer a reliable, economical, and environmentally conscious solution. As industries continue to seek materials that do not force a choice between performance and planetary responsibility, these versatile sheets will undoubtedly play an expanding role in building a more durable and sustainable future.