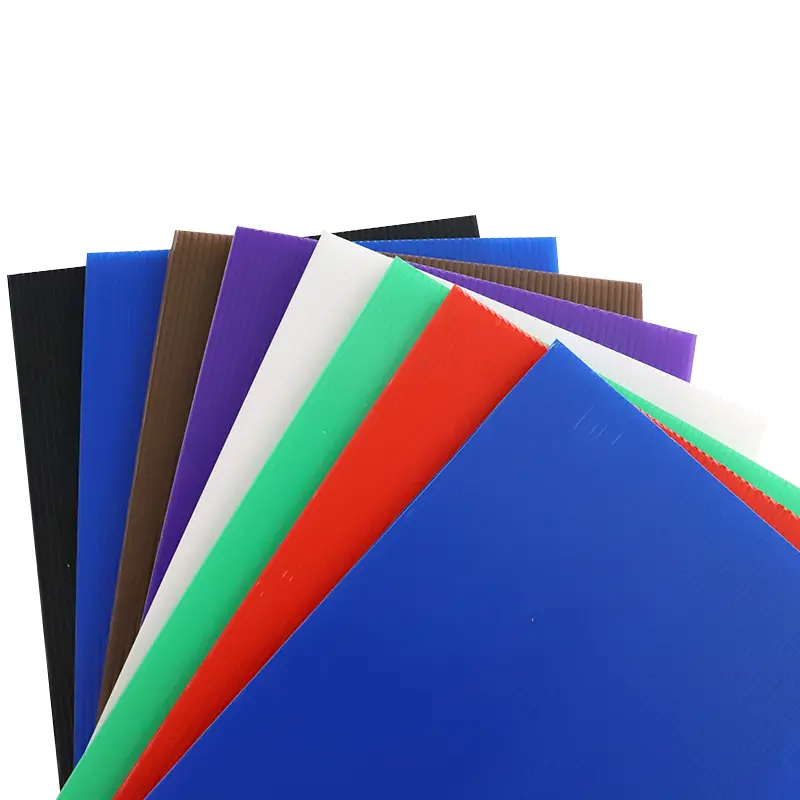

Overview of PP Hollow Sheet.PP hollow sheet (PP Hollow Sheet), also known as PP hollow board or plastic corrugated board, is a lightweight sheet made primarily from polypropylene. Its unique hollow structure offers an excellent balance between weight, strength, and cost, making it an ideal alternative to traditional packaging and construction materials.

This sheet is typically produced using co-extrusion technology. Through a precisely controlled extrusion process, regular longitudinal or transverse hollow channels are formed. These air cavities not only reduce the material's weight but also provide the sheet with excellent thermal insulation, sound insulation, and cushioning properties.Product Features and Advantages.Physical Properties.Lightweight: Density is only 0.92-0.94 g/cm³, 50%-70% lighter than traditional wood panels.High Strength: Special structural design provides excellent impact and compressive resistance (longitudinal compressive strength reaches 4-8 MPa).Various Thicknesses: Common thicknesses range from 2mm to 12mm, customizable upon request.Chemical Properties.Corrosion Resistance: Excellent resistance to acids, alkalis, salts, and most chemical solvents.Waterproof and Moisture-Proof: Water absorption rate <0.01%, completely unaffected by humid environments.Non-Toxic: Complies with FDA and EU food contact material standards.Environmentally Friendly.Recyclable: 100% recyclable, can be used in similar products or recycled.Reusable: Long service life, reusable for 5-8 years under normal conditions.Low Carbon Emissions: Production energy consumption is only 1/5 of that of steel and 1/8 of that of aluminum.Processability.Easy to Cut: Can be cut using common woodworking tools.Printable: The surface is suitable for various printing processes, including screen printing, offset printing, and digital printing.Thermoformable: Can be heat-bent when heated to 140-160°C.Production Process and Technology.Modern PP hollow board production lines primarily utilize a three-step "co-extrusion-calendering-cooling" process:Raw Material Preparation: PP resin is mixed with masterbatch, modifiers, and other materials in appropriate proportions.

Melt Extrusion: Melt-plasticized using a twin-screw extruder at 190-220°C.Compression Molding: The hollow structure is formed using specially designed molds.Cooling and Shaping: A multi-stage progressive cooling system ensures dimensional stability.Trimming and Winding: Precisely controls sheet width, with a maximum width of 3.2 meters.Recent technological breakthroughs include:Multi-layer co-extrusion technology (up to 7 layers).Micro-foaming technology (reducing weight by 15% without compromising strength).Online inspection system (enabling 100% quality control)Main Application Areas.Packaging Industry (approximately 45%).Logistics Turnover Boxes: Replace traditional wooden and cardboard boxes, reducing transportation costs.Electronic Product Packaging: Anti-static PP sheets for transporting precision instruments.Agricultural Product Packaging: Ventilation design extends the shelf life of fruits and vegetables.Building Decoration (approximately 30%).Temporary Building Fences: Lightweight, easy to install, and reusable.Interior Partitions: Provide excellent acoustic performance.Roof Lighting Panels: Light transmittance of 50%-85%.Advertising Display (approximately 15%).Display Board Backsheet: Weighs only one-third of KT board and is twice as strong.Outdoor Billboard: Weather-resistant formula protects against UV radiation.Other Emerging Applications (approximately 10%).Automotive Interiors: Reduces vehicle weight and improves fuel efficiency.Furniture Manufacturing: Creative DIY furniture materials.

Concurrently, with the advancement of 3D printing technology, recyclable PP hollow sheet materials may become a new consumable in additive manufacturing, further expanding their application. Collaborative innovation will be a key driver for the high-quality development of the PP hollow sheet industry. Optimizing the entire supply chain, from raw material modification and production processes to recycling, will create greater economic and social value.