Mantis Waterjet Cutting Brick

l Material: Co-polymer (Combination of PP and PE)

l Thickness: 4mm, 5mm, 6mm

l Size: 1# 3.85‘’x6‘’x48'' (97.8mmx152.4mmx1219.2mm), 2# 6‘’x6‘’x48'' (152.4mmx152.4mmx1219.2mm), different amounts of standard bricks can be used to constitute different size bricks as requirement.

l Weight: 11LBS (5KGS), 17.5LBS (7.9KGS)

l Color: Blue and White Core, Blue and Black Core, Black and White Core

l Application: Abrasive Waterjet Cutting, Only-water Cutting

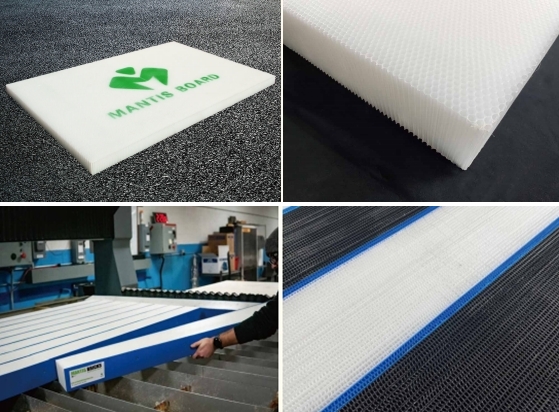

Mantis Waterjet Cutting Board

l Material: Co-polymer (Combination of PP and PE)

l Thickness: 6mm, 8mm

l Size: 1# 3.85‘’x30‘’x54.5'' (97.8mmx762mmx1384.mm), 2# 3‘’x30‘’x54.5'' (76.2mmx762mmx1384.3mm), 3# 2‘’x30‘’x54.5'' (50.8mmx762mmx1384.3mm), 4# 1200mmx800mmx46mm, different amounts of standard boards can be used to constitute different size bricks as requirement.

l Color: White

l Application: Innovative Cutting Surface For Waterjet

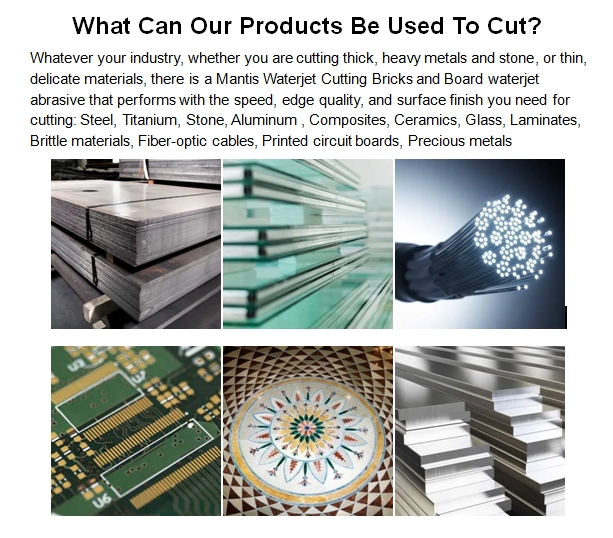

What is Mantis Waterjet Cutting Brick and Board?

Mantis Waterjet Cutting Bricks, a kind of waterjet cutting bricks, it is specially designed and engineered to provide a smooth, flat, uniform surface for small, brittle or delicate cutting materials during the waterjet cutting processes. Mantis Waterjet Cutting Bricks made of durable co-polymer (combination of polypropylene and polyethylene), the bricks use a laminated pattern to minimize splash back from the waterjet while draining water and debris away quickly and effectively. Individual waterjet cutting bricks make changing out worn bricks easy. Mantis Waterjet Cutting Bricks are used for abrasive waterjet cutting or only-water cutting, such as cutting metal, stone, plastic and composites, etc. There are many advantages Mantis Waterjet Cutting Bricks can bring to your waterjet cutting process, such as saving time and money.

Mantis Waterjet Cutting Board provides a innovative waterjet cutting surface. In the process of waterjet cutting, Mantis Waterjet Cutting Board provides a smooth, flat and uniform cutting operation surface, reducing the probability of cutting parts falling into the water tank, and to some extent reducing the water splashing that affects the work. Mantis Waterjet Cutting Board is made of durable co-polymer (polypropylene and polyethylene) materials with a honeycomb core structure. Mantis Waterjet Cutting Board is easy to repair the areas that are frequently cutting. It uses hot bonding instead of screws for fixing, so repairing Mantis Waterjet Cutting Board only requires a simple hot glue gun. When the damage occurs, cut off the damaged area of the board, use the hot glue gun to glue a new board of the same size to the Mantis Waterjet Cutting Board, then it can be used again.

Mantis Waterjet Cutting Brick

ü Lightweight - A standard brick weighs about 11 lbs. (5 kg), making it easy to change and rotate. ü Recyclable - The polypropylene and polyethylene material is 100% recyclable. ü Quieter Operation- Cutting noise is reduced, creating a quieter and more productive workspace. ü Cleaner Cutting - Internal design drains water away from the cutting area, reducing splash back. ü Durability - Made from a tough co-polymer material(combination of polypropylene and polyethylene), allowing for more cuts and greater savings. ü Easy to Install and Replace - Simply sit atop your existing material support slats. Custom sizes available for precision-fit. Replace sections at a time when well-worn.

|

Mantis Waterjet Cutting Board

ü Lightweight - Mantis Waterjet Cutting Board uses low-density honeycomb core structure which makes it easier to transport and saves on shipping costs. ü Recyclable - Both polypropylene and polyethylene materials are 100% green and recyclable. ü Quiet Operation - Reduce cutting noise to create a quieter and more efficient workspace. ü Clean Cut - Internal honeycomb design allows for faster water flow out of the cutting area, reducing water splashing. ü Durability - Made of tough polypropylene and polyethylene co-polymer material, allowing for more cutting operations to save more resources.

|

Product | Mantis Waterjet Cutting Brick | |

Material | Co-polymer (Combination of PP and PE) | |

Size | 1# 3.85‘’x6‘’x48'' (97.8mmx152.4mmx1219.2mm) | |

2# 6‘’x6‘’x48'' (152.4mmx152.4mmx1219.2mm) | ||

Thickness | 4mm, 5mm, 6mm | |

Weight | 11LBS (5KGS), 17.5LBS (7.9KGS) | |

Application | Provide a smooth, flat, uniform surface for small, brittle or delicate cutting materials during the waterjet cutting processes | |

Feature | Lightweight | A standard brick weighs 11 lbs, making it easy to change and rotate. |

Durability | Made from a tough polypropylene material, and will not separate, allowing for more cuts and greater savings. They are the most durable waterjet cutting bricks on the market. | |

Less Brick Debris | Easier on garnet removal systems. | |

Recyclable | The PP and PE material is 100% recyclable. | |

Part Retention | The flat, even cutting surface prevents parts from falling into the tank. | |

Better-Looking Parts | Mantis waterjet cutting bricks eliminate spray back that can mark the underside of parts. | |

Quieter Operation | Cutting noise is reduced, creating a quieter and more productive workspace. | |

Cleaner Cutting | Internal design drains water away from the cutting area, reducing splash back. | |

Flexibility | Mantis waterjet cutting bricks can be used with abrasive waterjet cutting and water-only cutting. | |

Color | Blue and White Core, Blue and Black Core, Black and White Core | |

Packing | Film ordinary packing or as your request. | |

Delivery Time | Generally within 10 working days, or it is according to your order. | |

Product | Mantis Waterjet Cutting Board | |

Material | Co-polymer (Combination of PP and PE) | |

Size | 1# 3.85‘’x30‘’x54.5'' (97.8mmx762mmx1384.3mm) | |

2# 3‘’x30‘’x54.5'' (76.2mmx762mmx1384.3mm) | ||

3# 2‘’x30‘’x54.5'' (50.8mmx762mmx1384.3mm), | ||

4# 1200mmx800mmx46mm | ||

Thickness | 6mm, 8mm | |

Application | Provide a smooth, flat, uniform surface for small, brittle or delicate cutting materials during the waterjet cutting processes | |

Feature | Stable Cutting Surface | Mantis Waterjet Cutting Board provides a stable cutting surface that greatly reduces the chance of losing parts in the waterjet tank and prevents splash-back that typically ruins jobs. |

Simple And Fast | You can create a typical 6′ x 12′ bed of Mantis Waterjet Cutting Board in a few minutes. | |

Long Lasting | Mantis Waterjet Cutting Board is easily repairable on repeatable cut areas thus increasing the life of the cutting surface. | |

Recyclable | The PP and PE material is 100% recyclable. | |

Tougher | There are no screws used due to the patented bonding process, making repairs to the Mantis Waterjet Cutting Board possible with a simple hot glue gun. | |

No More Heavy Lifting | Mantis Waterjet Cutting Board can save on shipping costs but does not affect the durability. | |

Cleaner Cutting | Internal design drains water away from the cutting area, reducing splash back. | |

Flexibility | Mantis Waterjet Cutting Board can be used with abrasive waterjet cutting and water-only cutting. | |

Color | White | |

Packing | Film ordinary packing or as your request. | |

Delivery Time | Generally within 10 working days, or it is according to your order. | |

Hot Sale Product Of Waterjet Cutting Industry

Why Choose our waterjet cutting parts?

Professional Team

With the power of a group of passionate and devoted people, high standard corrugated plastic products have been brought to the world at unbeatable prices, delivering value-added services to all our customers. With the development of Mantis company, more and more wonderful products and services will come in front of us very soon. The culture of Mantis company is one of discipline and focus on contributing to the corrugated plastic field and international trade services field. May all customers achieve great success in business and life by using Mantis Products and taking our services.

Experienced Manufacturer And Exporter

Jinan Mantis Company Ltd, founded in 2012, which has been in corrugated plastic businesses for over 10 years. The most satisfying products and most professional services have been brought to countless customers in the market.

FAQ

Q: What is Mantis Waterjet Cutting Brick and Board?

A: Mantis Waterjet Cutting Bricks is a kind of waterjet cutting bricks, it is specially designed and engineered to provide a smooth, flat, uniform surface for small, brittle or delicate cutting materials during the waterjet cutting processes. Mantis Waterjet Cutting Board provides a innovative waterjet cutting surface. In the process of waterjet cutting, Mantis Waterjet Cutting Board provides a smooth, flat and uniform cutting operation surface, reducing the probability of cutting parts falling into the water tank, and to some extent reducing the water splashing that affects the work.

Q: How to use and install after purchase Mantis Waterjet Cutting Brick?

A: Mantis Waterjet Cutting Bricks Product Manual: Step 1. Lay bricks perpendicular to the slates, cover the entire table or just a section. Step 2. Clamp the bricks in place so they don't migrate, it will increase the life of waterjet cutting bricks. Step 3. Screws or fasteners can be used to clamp the cutting materials in a place. Step 4. If abrasive is used, flip waterjet cutting bricks when the surface is worn to extend the life. Step 5. Raise the water level on the table of waterjet during cutting to increase brick life.

Q: How to use and install after purchase Mantis Waterjet Cutting Board?

A: Mantis Waterjet Cutting Board Product Manual: Step 1. Set the Mantis Waterjet Cutting Board on a part or all of the cutting table. Step 2. Fix the position of the Mantis Waterjet Cutting Board so that it will not move. Step 3. Screws or fasteners can be used to fix the cut material in the appropriate position on the Mantis Waterjet Cutting Board. Step 4. Mantis Waterjet Cutting Board can be flipped for use when it is worn out.

Q: Benefits of using Waterjet Cutting Bricks and Boards.

A: Besides preventing the object from slipping in between the grates, the waterjet brick provides even support for the object during the cutting process. You will also find it useful for cutting very soft or scratch-prone materials as it prevents frosting and marring from backsplash. Cut small parts, small parts will not fall into the tank. No need for programming “holding tabs”. Supports flexible materials provides a smooth, flat, uniform surface for flexible materials, such as sheet, metal, insulation, foam, silicone, cork, and other gasket materials, fabrics, etc. Reduces splash-back, helps channel water away from cut area. Helps reduce “frosting”, some materials are damaged by the jet reflecting off the slats and frosting or scaring the support surface. Mantis Waterjet Cutting Bricks and boards reduce or eliminate this effect. Easy to install & replace, Mantis Waterjet Cutting Bricks and boards simply sit atop your existing material support slats. Custom sizes available for precision-fit, replace sections at a time when well-worn. Durable polyethylene construction. Sturdy nailed design, maintains sturdy bond between planks when worn.

Q: How do I find prices for waterjet parts?

A: You can contact us via email, etc., and we will respond within 24 hours.

Q: Are Mantis Waterjet Cutting Bricks and boards recyclable?

A: Mantis Waterjet Cutting Bricks and boards are made out of polypropylene which is a recyclable plastic. Please note that the waste plastic from the bricks that has settled in your waterjet tank will need to be separated from the spent abrasive and the debris from the materials that have been cut. We recommend contacting your waste removal company to make sure they are willing to accept this material for recycling.

Q: Does Mantis offer free shipping?

A: Mantis is a professional manufacturer and exporter, we will calculate the international shipping cost based on your purchase quantity.

Q: Can glass be cut on a waterjet?

A: Yes, glass can be cut on a waterjet. Depending on the thickness, glass may flex during cutting and therefore should be fully supported on a flat level surface. Mantis Waterjet Cutting Bricks and boards are a good support and will reduce the chance of frosting on the bottom of the glass.

Q: What is the delivery time?

A: Generally, with the 10 working days.

Q: How can I make a payment?

A: Mantis offers multiple ways to make a payment. The preferred method of payment is T/T.